Working with physical goods inevitably involves moving a lot of stuff around. Some boxes get stored, others go out the door, and there’s a flow to it. When that flow

Working with physical goods inevitably involves moving a lot of stuff around. Some boxes get stored, others go out the door, and there’s a flow to it. When that flow is smooth, nobody notices, but when it’s not, things can go south very dramatically and very fast.

Material handling is all about the behind-the-scenes logistics of how a business moves, stores, protects, and controls goods from the moment they arrive until they leave a facility again. Let’s break down what that actually means in practice.

Practical Definition

Industry groups like MHI describe these activities as “the movement, protection, storage and control of materials and products throughout the process of their manufacture and distribution, consumption and disposal.”

If this sounds a bit too abstract, I’m with you 100%, so let’s translate it into something a bit more tangible that you can picture on your floor:

- Movement: Whether items are moved by hand, cart, pallet jack, forklift, conveyor, shuttle, or robot. Just like warehouses, real estate material logistics ensures timely movement of construction supplies to different sites.

- Storage: Whether you park things on floor pallets, racks, bins, vertical towers, or mezzanines.

- Protection: Keeping goods, equipment, and people safe with packaging, guarding, safe travel paths, etc.

- Control: Knowing where everything is and where it’s going. This is where labels, barcodes, WMS, and standard work instructions come in.

Breaking things down even further into a practical example, this means that an operation that ships 50 orders a day out of a small back room can rely on no more than a well-maintained spreadsheet and a couple of shelves and carts.

However, a multi-aisle distribution center working with hundreds of SKUs likely needs sorters, conveyors, and perhaps an automated storage system.

Either operation is attempting to solve the problem of how to move things with the least possible waste and risk, and they’re doing it in the most efficient way based on their respective situation.

Main Types of Systems

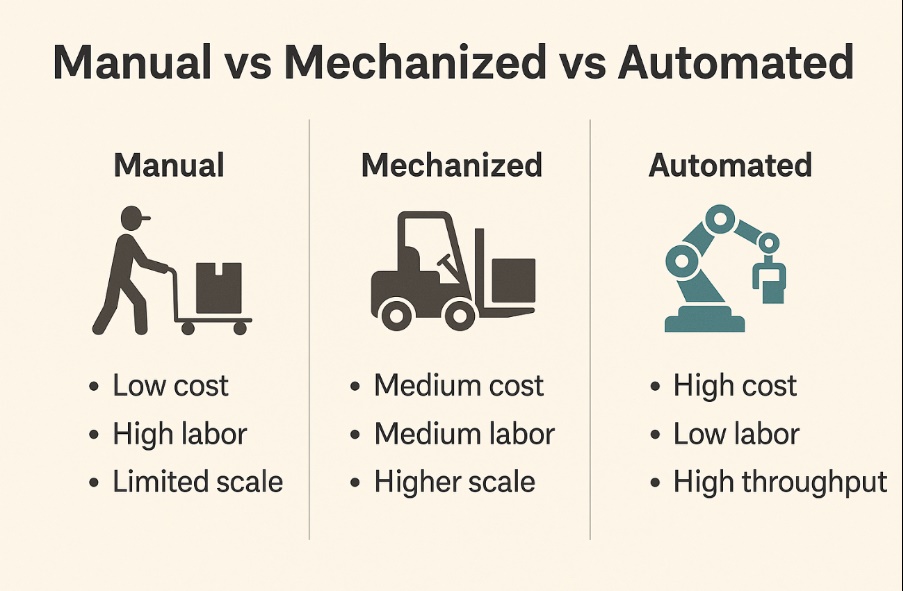

Most facilities use some mix of three broad approaches:

- Manual methods: Employees move items by hand with basic tools like carts, dollies, and hand trucks. If volumes are low and items are light, this works just fine, but risk rises quickly as loads get heavier or walking distances grow.

- Mechanized equipment: Here, you add forklifts, pallet jacks, stackers, simple conveyors, and lift tables. You still rely heavily on people, but you reduce heavy lifting and speed up repetitive moves like pallet transfers and line feeding.

- Automated and robotic solutions: Vertical storage towers, shuttles, automatic conveyors, and mobile robots (AGVs/AMRs) bring goods to people instead of the other way around. These systems shine in higher-volume operations where every second and every square foot matters.

The right mix depends on your volume, product mix, labor market, and growth plans. A common pattern is to start by organizing and standardizing manual processes, then add targeted mechanized tools, and only then consider more capital-intensive automation where it clearly pays off.

Key Processes in a Typical Warehouse

No matter how big or small your facility is, you’ll usually see the same core stages. The better each stage runs, the better your overall flow.

Receiving

Trucks arrive, you unload, check quantities and quality, and label items. Small improvements like clear staging zones and fast labeling prevent chaos from cascading into every other step. \

Put-away and replenishment

Goods move from the dock into their storage locations. Putting fast-moving items close to packing and grouping related items together can dramatically cut walking time and errors.

Storage and inventory control

Your goal here is the right density without turning every pick into a treasure hunt. Visible labels and a system of record that matches reality are non-negotiable.

Picking

This is often the single most expensive activity inside the building. Workers or robots pull items to fill orders in batches, zones, or waves. Reducing travel distance and using smarter storage locations pays off quickly.

Packing, value-added services, and staging

Here, you verify items and prepare shipments by carrier or route. Standardizing workstations and providing tape dispensers, scales, label printers, and height-adjustable tables boosts both speed and ergonomics.

Shipping and returns

Finally, boxes or pallets are loaded onto outbound trucks, and returned items are processed back into inventory. Clean, clearly marked docks and repeatable processes here prevent mix-ups and rework. During receiving, performing quality checks, labeling, and following standard work instructions is critical — just like in building quality systems that scale.

It’s More Important Than You Think

All this is easy to treat as background details until you take a look at the actual numbers.

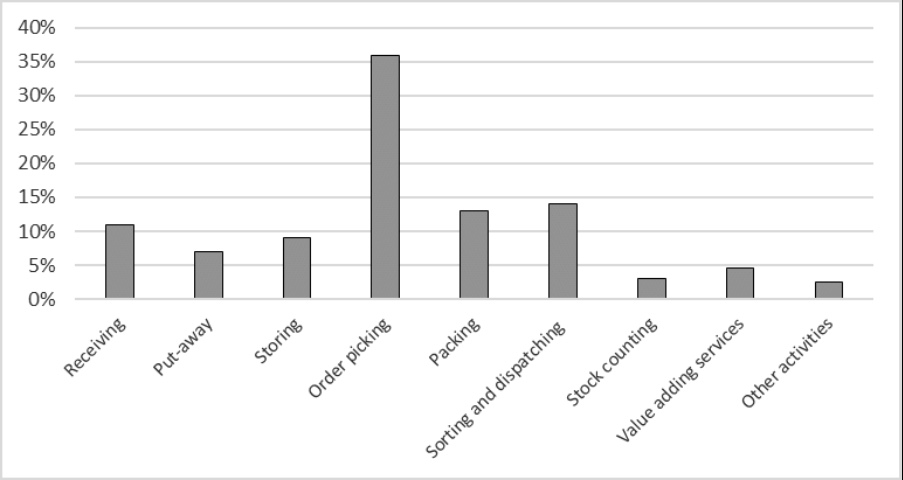

Research on warehouse operations has found that worldwide warehousing activities cost companies around €300 billion per year, and that cost is growing as supply chains and e-commerce get more complex.

Other studies show that warehousing can account for around 20% of overall logistics costs for many companies, and that order picking alone can make up more than 36% of total warehouse operating expenses, because it’s labor-intensive and often involves a lot of walking and searching.

Translated into everyday language, this means that every extra “touch” where a box is moved twice quietly adds a labor cost that adds up over time, and that every extra meter walked wastes precious time.

So, when you improve how goods move and how people find them, you’re attacking one of the biggest cost centers in your supply chain.

Respond to this article with emojis