Item data management offers a solution to these persistent challenges. By centralizing all product, inventory, and asset information in a single accessible system, businesses can transform their operations from reactive

Item data management offers a solution to these persistent challenges. By centralizing all product, inventory, and asset information in a single accessible system, businesses can transform their operations from reactive to proactive, from error-prone to precise, and from isolated to integrated.

In this comprehensive guide, we’ll explore how item database management can revolutionize your inventory operations, boost productivity, and provide the foundation for sustainable business growth.

What is Item Database Management?

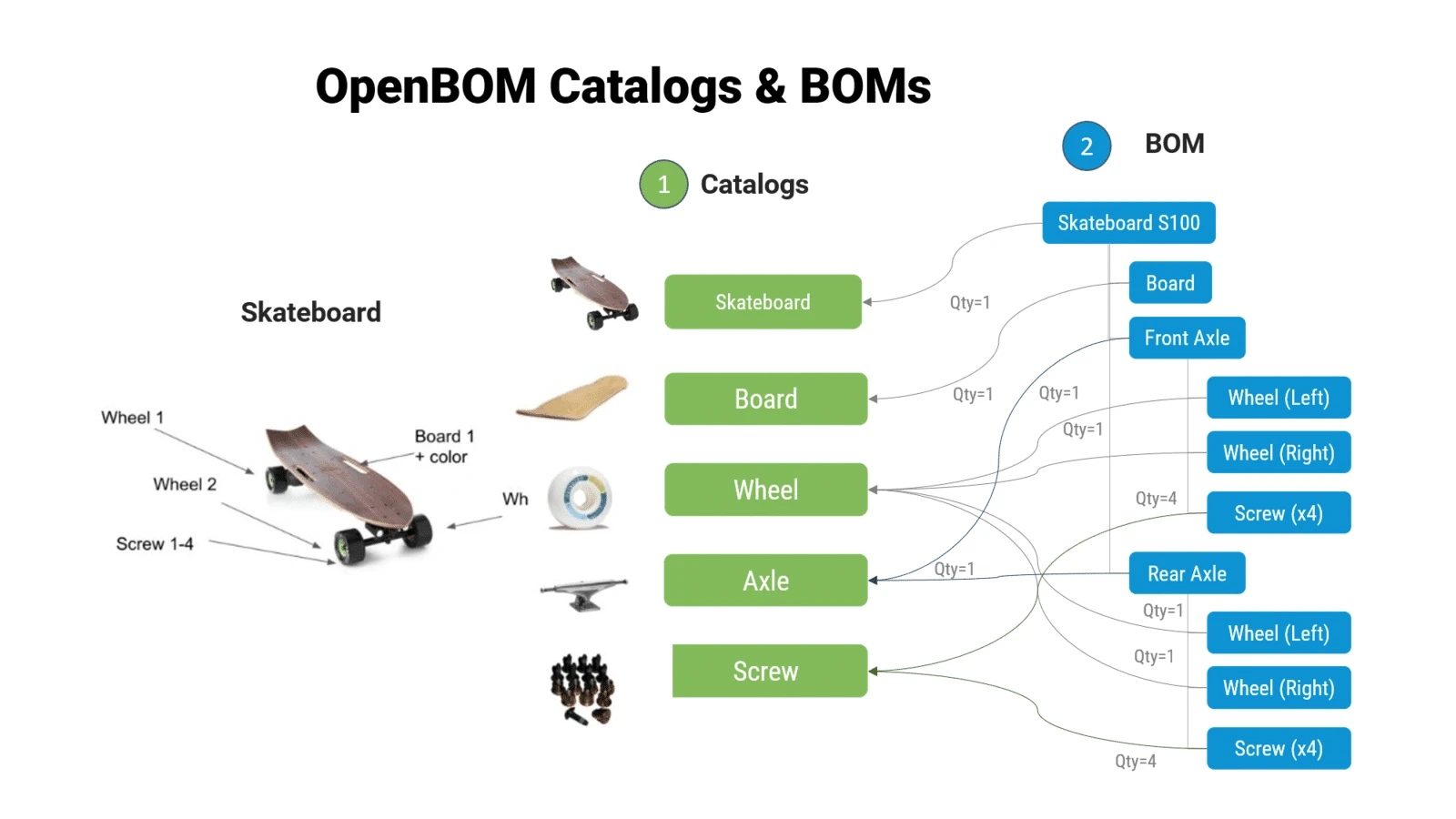

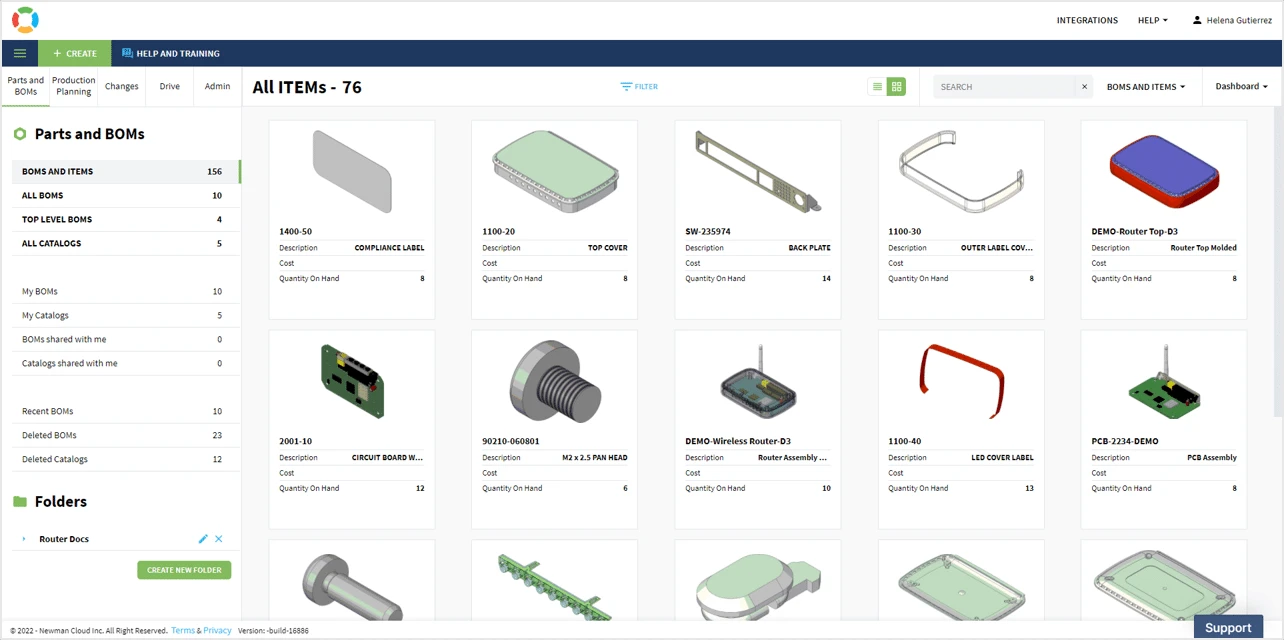

Item database management is the discipline of designing, maintaining, and using databases specifically to organize, track, and control all data related to physical and digital items a business manages. This includes products, assets, materials, equipment, and consumables that form the backbone of daily operations.

Unlike traditional spreadsheet-based inventory tracking, modern item database systems are built on structured data models with robust schema and referential integrity. These systems are optimized for multi-user environments, multiple locations, and real-time operations that today’s businesses demand.

Barcode and RFID Integration

Modern item database management leverages automatic identification technologies to accelerate transactions and eliminate manual data entry errors. These technologies transform inventory operations from slow, error-prone manual processes to fast, accurate automated workflows.

Barcode Scanning Capabilities

Barcode integration enables lightning-fast item identification and transaction processing. Mobile scanners, tablets, and smartphones can instantly look up items, process receipts and issues, and perform inventory adjustments. One-dimensional and two-dimensional barcodes support different data requirements and scanning environments.

The system generates barcode labels for all items using industry-standard formats. These labels can include human-readable information such as item descriptions and prices alongside machine-readable codes. Label printing integrates directly with the database to ensure accuracy and consistency.

QR Code Implementation

QR codes extend barcode capabilities by storing more data and enabling dynamic linking. Items can have QR codes that link to product documentation, warranty information, maintenance records, or training materials. This creates a bridge between physical items and digital information resources.

Mobile devices can scan QR codes to access real-time information about specific items, including current location, maintenance history, and usage instructions. This capability is particularly valuable for complex equipment or items requiring specialized handling procedures.

RFID Technology Integration

RFID technology enables bulk reading of multiple items simultaneously, dramatically accelerating inventory processes. Passive and active RFID tags integrate with reader infrastructure to support high-speed cycle counting and asset tracking. RFID is particularly valuable for high-volume operations or high-value asset management.

The technology supports various read ranges and environments, from close-proximity item-level tracking to long-range vehicle and container tracking. Integration with the item database enables real-time location tracking and automated inventory updates as items move through facilities.

Asset Tagging Systems

Physical asset tagging provides robust tracking throughout item lifecycles. Each item or piece of equipment receives a unique physical identifier that links to comprehensive database records. Asset tags can incorporate multiple technologies such as barcodes, RFID, and QR codes to support different operational requirements.

Durable asset tags withstand harsh environments including outdoor exposure, chemical contact, and high temperatures. The tagging system supports various tag types and materials to match specific environmental and durability requirements while maintaining readability throughout asset lifecycles.

Reporting and Analytics

Advanced reporting and analytics capabilities transform raw inventory data into actionable business intelligence. Modern item database systems provide both standard reports and customizable analytics tools that support strategic decision-making and operational optimization. When analytics and automated workflows are combined through CRM‑enabled systems, businesses experience faster reporting cycles and fewer errors — you can explore CRM‑led success strategies in this smart CRM guide.

Comprehensive Inventory Reports

Real-time and historical inventory reports provide detailed insights into stock levels, valuation, turnover rates, and shrinkage patterns. Standard reports include inventory aging analysis, stock status summaries, and movement histories that support routine operational decisions.

Advanced reporting capabilities enable custom report creation using drag-and-drop interfaces or SQL-based query tools. Users can create reports that combine inventory data with sales, purchasing, and financial information to generate comprehensive business insights.

Sales Velocity Analysis

Sales velocity analysis identifies fast-selling and slow-moving products, providing critical input for demand forecasting and inventory optimization. The system analyzes historical sales patterns, seasonal trends, and current velocity to predict future demand and recommend optimal stock levels.

Velocity analysis can be segmented by location, customer type, sales channel, or time period to identify specific patterns and opportunities. This granular analysis supports targeted inventory strategies that maximize turnover while minimizing stockout risks.

ABC Analysis for Inventory Prioritization

ABC analysis ranks inventory items by value and importance, helping prioritize management attention and optimize stocking strategies. The system automatically categorizes items into A (high-value), B (medium-value), and C (low-value) categories based on configurable criteria such as annual dollar volume or gross margin contribution.

This categorization supports differentiated inventory policies where high-value items receive closer monitoring and more frequent reviews while low-value items operate with broader tolerances and less frequent attention. The approach optimizes management time while maintaining appropriate control over critical inventory.

Customizable Dashboard Creation

Visual dashboards provide real-time key performance indicators that support quick decision-making. Customizable widgets display metrics such as out-of-stock percentages, inventory turnover rates, and average days on shelf. Dashboards can be personalized by user role and responsibility area.

Export and Integration Capabilities

Flexible export functionality enables data sharing with external business intelligence tools, regulatory agencies, and business partners. Standard export formats include Excel, CSV, and PDF, while API connections support real-time data sharing with other business applications.

Integration with business intelligence platforms enables advanced analytics using specialized tools while leveraging the item database as the authoritative data source. This approach combines the operational benefits of specialized inventory management with the analytical power of dedicated BI platforms.

Business Intelligence Features

Advanced item database systems incorporate sophisticated business intelligence capabilities that transform historical data into predictive insights and strategic recommendations.

Trend Analysis and Forecasting

Comprehensive trend analysis identifies seasonal demand patterns, regional variations, and emerging market shifts. The system analyzes multiple years of historical data to identify recurring patterns while considering recent trends that might indicate changing market conditions.

Forecasting algorithms use this analysis to predict future demand with statistical confidence intervals. These predictions support better purchasing decisions, assortment planning, and resource allocation. Machine learning capabilities enable the system to improve forecast accuracy over time by learning from prediction errors.

Cost and ROI Analysis

Detailed cost analysis breaks down inventory expenses beyond simple purchase prices to include holding costs, obsolescence, and opportunity costs. The system calculates true inventory carrying costs and return on investment metrics that support strategic inventory decisions.

ROI analysis can evaluate the financial impact of different inventory strategies, supplier relationships, and stocking policies. This analysis supports data-driven decisions about inventory investments and helps justify inventory optimization initiatives.

Supplier Performance Analytics

Comprehensive supplier performance tracking includes fulfillment rates, on-time delivery, quality scores, and price trend analysis. The system maintains scorecards for each supplier that combine multiple performance dimensions into overall ratings.

Performance analytics can identify the best suppliers for different types of purchases and highlight opportunities for supplier development or replacement. This analysis supports strategic sourcing decisions and supplier relationship management.

Predictive Analytics

Advanced predictive analytics use machine learning algorithms to identify patterns that might not be apparent through traditional analysis. The system can predict which items are likely to become obsolete, identify optimal reorder timing, and forecast demand spikes or declines.

Predictive capabilities extend to maintenance requirements for equipment and assets, helping organizations optimize maintenance schedules and prevent unexpected failures. These insights support proactive rather than reactive management approaches.

Common Implementation Challenges

Understanding and preparing for common implementation challenges can significantly improve project success rates and user satisfaction. Most challenges can be mitigated through proper planning and realistic expectations.

Data Accuracy During Migration

Data migration often reveals the extent of data quality problems in existing systems. Duplicate records, inconsistent naming conventions, and missing information can complicate migration efforts and undermine user confidence in the new system. Extensive data cleansing may be required before migration can proceed.

Mapping errors during migration can create ongoing operational problems that are difficult to identify and correct. Validation processes must verify that migrated data accurately represents existing inventory while conforming to new system requirements. Test migrations using representative data samples help identify potential issues before full migration.

Integration Complexity

Connecting new inventory systems with existing business applications can be more complex than anticipated, especially when dealing with legacy systems or custom applications. Integration requirements may necessitate custom development work that increases implementation time and cost.

Data format incompatibilities and different business logic between systems can create ongoing synchronization challenges. Thorough testing of integration scenarios helps identify potential issues before they affect live operations. Fallback procedures ensure business continuity if integration problems occur.

Setup and Configuration Time

Initial system configuration requires careful consideration of business requirements and workflow design. Customization needs may not be fully apparent until users begin working with the system. Configuration changes during implementation can extend timelines and increase costs.

Complex approval workflows, user permission structures, and integration requirements can significantly extend setup timeframes. Realistic project timelines must account for the iterative nature of configuration refinement and user feedback incorporation.

Industry-Specific Applications

Different industries have unique requirements for item database management, driven by regulatory requirements, operational characteristics, and customer expectations. Understanding industry-specific applications helps businesses identify relevant features and implementation strategies.

Retail Inventory Management

Retail operations must manage thousands of SKUs across multiple locations while supporting omnichannel sales strategies. Real-time inventory synchronization prevents overselling across channels while automated replenishment maintains optimal stock levels. Seasonal demand patterns require sophisticated forecasting capabilities.

Shrinkage reduction through improved tracking and audit capabilities can significantly impact profitability. Integration with point-of-sale systems enables immediate inventory updates and loss prevention capabilities. Category management features support assortment optimization and vendor performance analysis.

Manufacturing Item Tracking

Manufacturing operations require tracking of raw materials, work-in-progress, and finished goods through complex production processes. Bill of materials integration ensures that component availability supports production schedules. Lot and serial number tracking supports quality control and recall procedures.

Equipment maintenance tracking helps optimize production uptime and maintenance costs. Integration with production planning systems ensures that material availability supports manufacturing schedules while minimizing excess inventory.

Construction Tool and Equipment Tracking

Construction operations involve tracking tools and equipment across multiple job sites and varying environmental conditions. Check-in/check-out capabilities ensure tool accountability and prevent loss. GPS tracking integration supports location monitoring for high-value equipment.

Maintenance scheduling ensures equipment reliability and safety compliance. Cost tracking by project enables accurate job costing and profitability analysis. Rental equipment integration helps optimize rent-versus-buy decisions.

Restaurant Supply Management

Food service operations require real-time tracking of perishable ingredients with strict expiration date monitoring. Recipe cost control capabilities help maintain consistent food costs and profitability. Supplier integration supports efficient ordering and receiving processes.

Waste tracking identifies opportunities for cost reduction and process improvement. Integration with point-of-sale systems enables automatic deduction of ingredients when menu items are sold, maintaining accurate inventory levels for perishable goods.

Future Trends in Item Database Management

The evolution of item database management continues to accelerate, driven by advances in artificial intelligence, Internet of Things technology, and changing business requirements. Understanding these trends helps businesses prepare for future opportunities and requirements.

Artificial Intelligence Integration

AI-powered demand forecasting uses machine learning algorithms to analyze complex patterns in historical data and predict future demand with improved accuracy. These systems learn from forecast errors and continuously improve prediction quality over time.

Smart reordering algorithms optimize inventory levels by considering multiple factors including seasonal patterns, supplier lead times, carrying costs, and stockout risks. These systems can automatically adjust reorder parameters as business conditions change.

IoT Sensor Technology

Internet of Things sensors enable automated inventory tracking through shelf sensors, smart bins, and equipment trackers. These devices can monitor inventory levels, environmental conditions, and usage patterns without human intervention.

Real-time location tracking using IoT devices provides continuous visibility into item locations and movements. This capability is particularly valuable for high-value assets and equipment that move frequently between locations.

Conclusion

The benefits extend far beyond simple inventory tracking. Improved accuracy reduces costly errors, automation saves time and labor, and comprehensive analytics enable data-driven decision making. Integration capabilities create unified business processes that eliminate silos and improve operational efficiency.

For businesses currently relying on spreadsheets or manual tracking methods, the transition to modern item database management offers immediate operational improvements and long-term strategic advantages. The technology has matured to the point where implementation is straightforward, costs are reasonable, and return on investment is typically realized within 12-18 months.

Whether you manage a small retail operation or a complex manufacturing enterprise, item database management provides the foundation for scalable, efficient, and profitable inventory operations. The question isn’t whether to implement these systems, but rather how quickly you can begin realizing their benefits for your business.

Respond to this article with emojis